wheat flour machine business

A complete set of wheat flour machines includes many parts. Its installation procedure is relatively complicated. Sometimes it even takes several days to complete the installation. After the installation is completed, a series of debugging and test runs are required, so it is necessary to use it during use. Operate by the regulations and seek professional help if you encounter any problems.

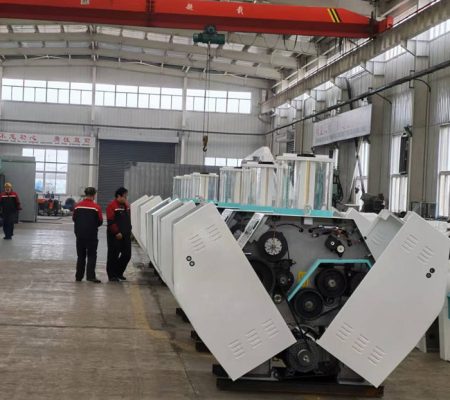

Small scale wheat flour machines for sale

The best-selling 10TPD small scale wheat flour milling plant, which can produce 10T of wheat flour per day, is suitable for small-scale mills. It has the advantages of low noise, power-saving, small footprint, high output, good powder quality, easy installation, and simple operation.

10tpd commercial wheat flour milling machine processing process

Cleaning part

The combined cleaning machine is chosen to remove the large& small impurities and stones from the grain.

Washing part

Place the watered wheat in the wheat moistening warehouse for 14-18 hours, so that the water of the epidermis enters the wheat core, and prepares for the later grinding stone to peel off the epidermis.

Milling part

In the latest section we call to mill section, By using the 2250 roller mill, the wheat flour will be milled more smoothly and evenly. After that, you can put the bag on the outlet port and then pack.

What problems will the wheat flour machine encounter?

Standardized operations

When installing a complete set of small wheat flour machines, you need to pay attention to the correct installation method. The installer must understand the system composition of the wheat flour mill machinery. Its system corresponds to its processing flow, such as a destoning system for screening raw materials and removing impurities.

Master device configuration

We need to have a general understanding of the various configurations of the wheat flour mill machine. When the equipment fails, we can find personnel to inspect and disassemble it as soon as possible to eliminate the fault as soon as possible. When replacing parts, try to choose ones that are universal, highly standardized, and interchangeable, so that when the equipment fails to work properly, the problematic parts can be quickly replaced without affecting the normal production of the flour machine.

Introduce advanced technology

The wheat flour machine manufacturers need to understand the technical characteristics and constantly introduce new technologies and methods into product design and manufacturing to make equipment use, operation, and maintenance more convenient, and with greater reliability and stability.

Buy wheat Processing Machine from Hanzhong Burt Machinery