wheat final finished product

In today’s flour mill machinery market, the quality of the equipment is uneven. Many grain milling machine manufacturers have difficulty making a choice when purchasing flour mill machinery.

The staff of Fire Phoenix Flour Machine told everyone that when purchasing an industrial grain milling machine, you must choose good quality flour machinery so that you can produce good flour and protect everyone’s health.

When we use complete sets of wheat milling machine, we have the following requirements:

- Reasonable structural design.

- Good thermal insulation performance.

- Sealing materials and adhesive technology are reliable.

- The sieve grid and sieve path are reasonable.

- Strict material selection and perfect manufacturing technology.

- Correct use and maintenance techniques.

In response to this requirement, new types of wheat flour machine have appeared on the market, which are more intelligent, large-scale, easy to operate, and have a more detailed classification of flour processing grades.

A good grain milling machine does not destroy the structure of wheat when processing and crushing it, but peels the wheat apart after a certain pretreatment process. Its fine processing changes the size and shape of wheat and in-process products, effectively separating endosperm, wheat bran, and embryo(read more: How much does the automatic flour mill mini plant cost).

The structure of the new wheat grinding machine is all made of stainless steel. The material has a beautiful appearance. The stainless steel material does not rust and is resistant to high temperatures. The absence of powder rust does not affect the processing of raw grains.

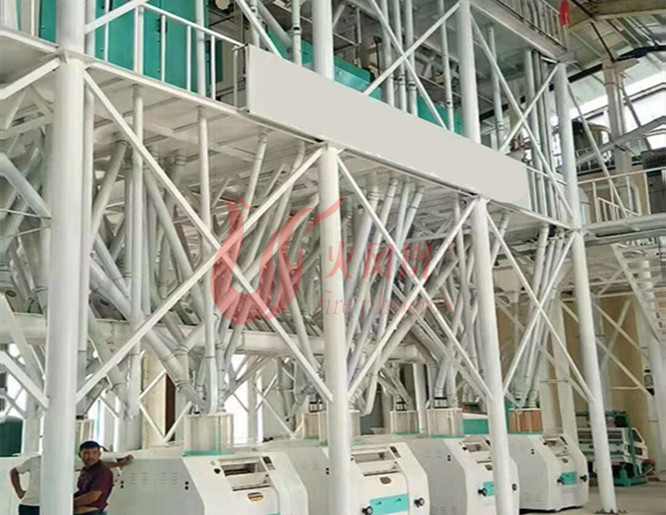

50 tons Wheat Flour Milling Plant video

Choosing a good industrial grain milling machine factory will make your life more convenient and colorful. A good flour mill machinery will bring good, healthy, and green flour so that you and your family can eat strong and good flour. What a blessing it will be a thing.