Nowadays, with the continuous deepening of technological research, the performance of wheat roller flour mill machinery is becoming more and more perfect, and the requirements are becoming more and more stringent.

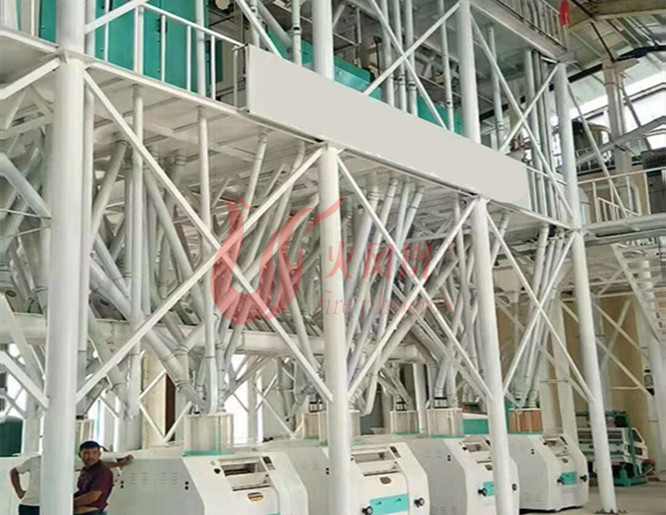

wheat roller flour milling plant machinery

If you want to process good products, you must be cautious in choosing machinery and equipment. Of course, expensive things naturally have expensive reasons, and high-quality products will not be cheap, so we must be cautious during use, and regular maintenance is also the key.

1. The system configuration of the wheat roller flour mill is very complicated. If you want to reduce the failure rate, you need to conduct regular inspections and develop a good habit of regular inspections. If you encounter a particularly large temperature change, especially when the temperature is low, before using the wheat processing equipment, you should pay attention to turning on the machine and letting the equipment idle for a few minutes.

2. After using the wheat flour milling machine, we must do a good job of cleaning in the later stage. After all, in the process of wheat processing and production, it is inevitable that some materials will remain, which will also cause wear and tear in some parts. We need to pay attention to these aspects during the cleaning and inspection process and do a good job of cleaning and replacing vulnerable parts.

3. When the temperature is low, we should also take anti-freeze measures.

4. Before the wheat milling machine is produced, it is necessary to check the humidity and quantity of the raw materials and make appropriate adjustments. After all, the quality of the raw grain has a great impact on the later grinding system, that is, the operation of the bearings, the spacing of the grinding rollers, etc., so we have to focus on cleaning the raw grain.

100tpd wheat milling machine

100 tons of wheat roller flour mill machine processing video

In addition, if the wheat milling plant wants to improve the quality of the finished product, it is not only affected by the quality of the machine itself but also by the reasonableness of the various parameters and component settings during the processing process. It will also have a great impact on its effect. Therefore, it should be noted that before the machine is officially used, the personnel can operate normally and smoothly, and they must be proficient in its operation process.