wheat final finished product

No matter how advanced human science and technology are, it cannot get rid of the demand for food crops. This is the basic reason why food companies can stand in the global market for a long time.

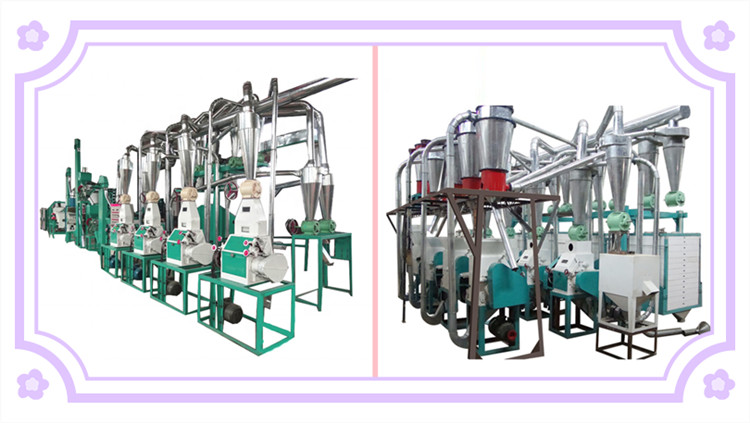

As a key grain production line, wheat has attracted much attention. A fully automatic flour mill mini plant as the main equipment for processing wheat, is of course very important.

Today’s flour mill machinery has introduced automation and informatization and has also obtained some patents in technology. Everyone is reassured in this aspect, but when it comes to price, it is the focus of many manufacturers. The price of a mill flour machine must be based on Different outputs, different processes, processes, equipment quality, and configurations. For specific automatic flour mill plant prices, you need to introduce your needs in detail. Only after engineers design for you can you get detailed prices.

automatic flour mill mini plant

Everyone should know that processing wheat into finished products requires many processes. These links are interlocked and indispensable. Moreover, the processing of different qualities of raw grains, different processed products, the size of the site, etc. are all closely related to the configuration of the equipment. which results in different prices of equipment.

The price of a 20-ton commercial wheat milling machine is US$21,800 to US$29,800, which depends on the customer’s configuration.

You know, a set of flour mill mini plant contains many supporting equipment. For example, a 100-ton wheat flour mill plant generally includes bucket elevators, vibrating screens, magnetic separators, low-pressure fans, destoners, sand roller peeling machines, bucket elevators, silos, sand roller peeling machines, and bucket elevators.

The equipment included in the equipment of different tonnages may be different. From this, it seems that those customers who ask how much the flour factory machine price is difficult to get. The quote you want is because we really can’t quote accurately.

Therefore, when customers inquire about flour milling machine, they need to first explain how much output they need and what configuration they need, so that they can give a rough range. When consumers make purchases of flour mill mini plant, they need to clarify their needs and then choose appropriate products.